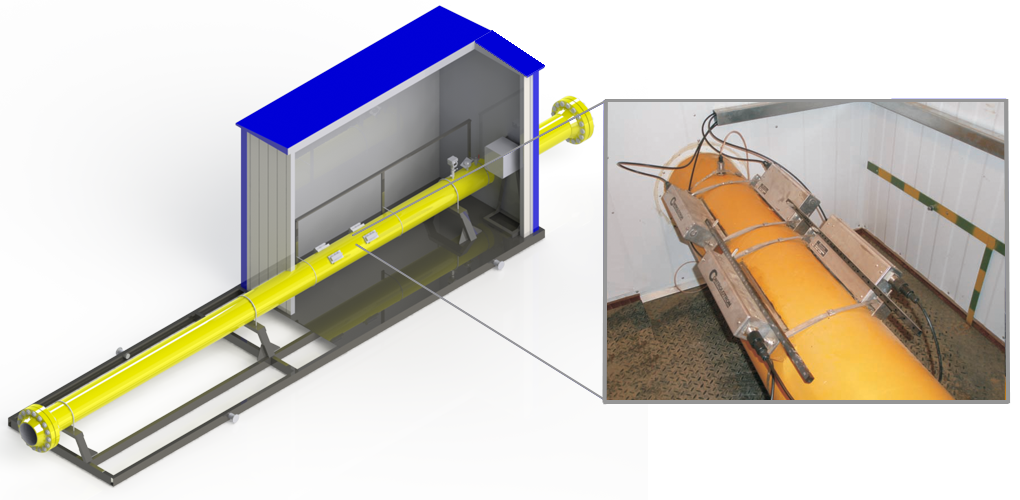

The product consists of a process and hardware blocks. A measuring pipe with flow sensors, temperature and pressure, as well as the tap for connection of the probe are placed in the technological block.

Block "Hardware" is a heated block-box in which a power cabinet, control cabinet, closet, meter calculator «Controlotron» and automatic fire-extinguishing system are allocated. Flow Computer provides measurement data in digital or analog form and is equipped with a data logger for storage and administration of the program parameters of the measuring object (pipe). In addition there is a set sound velocity data in various liquids and gases depending on the temperature for identification (recognition) of the type of the working environment and its characteristics. Flow Computercalculates the flow rate of gas, reduced to normal conditions and mass flow rate of the gas in accordance with GOST 30319.2 when connected temperature sensor and pressure sensor.

Features

The use of ultrasonic flow overhead sensors eliminates the bypass line with shut-off valves, that significantly reduces the cost and simplifies the design compared to analogs. A distinctive feature of the used meteris is the ability to measure flow in both (forward and reverse) flow direction, that greatly improves the accuracy of measurement at the real object. Life support system and remotely implemented on the base of the control controller «Unitronics».

The basis for metering unit is the ultrasonic flow versatile multifunctional meter"System 1010/1020," by the company «Controlotron Corporation», which consists of a flow computer and overhead ultrasonic sensors.

The flowmeter provides two modes of operation: time-pulse (for clean environments) and Doppler (for foul). Depending on the accuracy and application conditionsin four types of sensors are available.

The Wide Beam Technology Wide-Beamtm and ZeroMatictm used in the flowmeter allow to measure gas flow in the presence of "liquid phase" and to perform automatic calibration "zero" in the proces.